Väderstad has long-standing collaborations with higher education institutes such as Linköping University, KTH, University of Gävle, Uppsala University, Luleå University of Technology and University West. We also have a close collaboration in measurement technology with Exova Metech and with the Nordics’ largest producer of commercial steel, SSAB. The laboratory extends the potential of these collaborations, as much of the experimental work can be carried out on site, close to the

manufacturing industry.

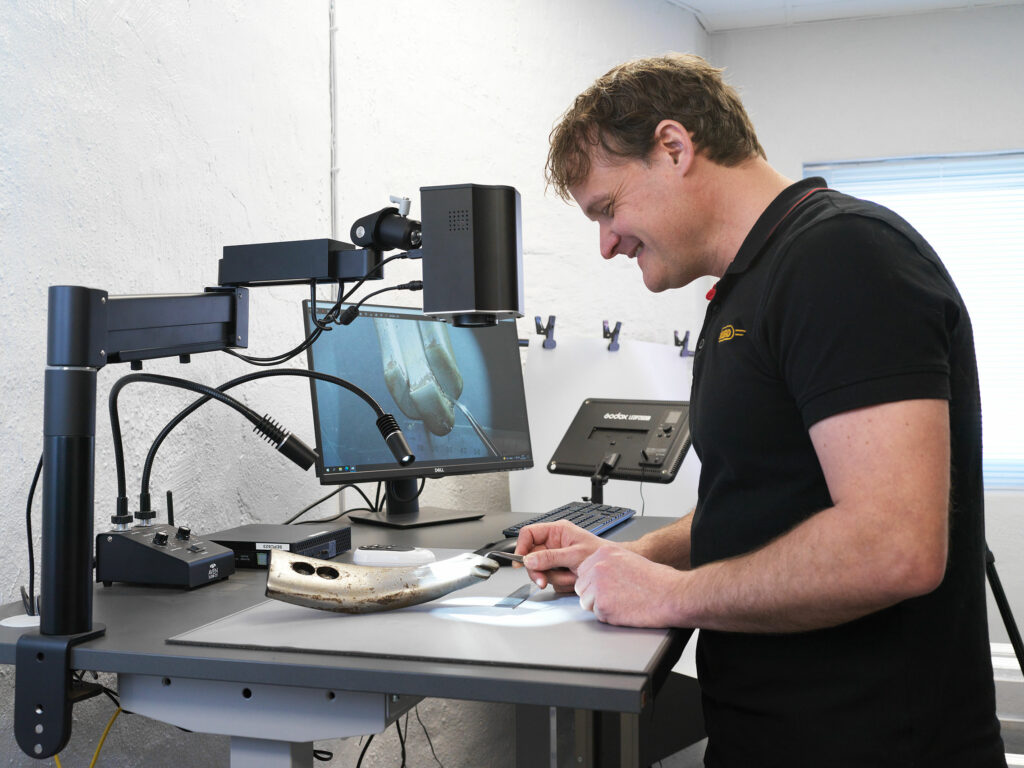

The best technique is not always a guarantee of perfect results – it also requires large amounts of knowledge. That is why we are very proud of our employees, where we have, among other things, recruited one of the country’s foremost metallurgists. We constantly strive to form as good a breeding ground as possible for the company’s competence development. This is how we have the privilege of having absolutely

world-class employees.

Tel: +46 493-534 10

Kvarngatan 1, SE-594 72 Överum, Sweden

Copyright: Väderstad Components AB. All rights reserved